Wine, by definition, is an alcoholic drink made from fermented grape juice. Grapes are unique since they are the only fruit with sugars levels that can withstand natural fermentation with stable and constant results. Of course, other fruits can be fermented. But, without the addition of yeast nutrients, acid, or sugar, they might spoil.

History of Fermentation

Even though the chemistry of alcoholic fermentation remained unknown until the 19th Century, the results of this process were familiar for at least 7,000 years.

Fermentation in Egypt and China

In fact, fermented fruit juice, grain, and honey have been made for thousands of years. Likewise, fermented beverages seemed to have existed as early as Ancient Egypt, and there is even evidence of an alcoholic drink in China around 7000 BC. In India, evidence suggests that a rice-based alcoholic beverage was consumed from 2000 to 3000 BC. That said, the Egyptians drank a distant relative to wine, too. But it was completely different from what we consider wine to be today, since it was a mixture of white, red, pink, and green grapes with dates and pomegranates.

Wine in Greece

Since 2700 BC, the Babylonians and Greeks worshipped wine gods and goddesses. In Greece, mead was the first alcoholic beverage to become famous. It was a fermented drink made from water and honey. During this period, Greeks produced quality wine. It is thought that the joys of wine were introduced to them by Phoenician traders. Similarly, as the Phoenicians introduced wine to Greeks, Alexander the Great introduced the drink to Asia.

Wine also had religious status in Greece. Greeks considered it the juice of the Gods. Drunkenness, however, was frowned upon because it altered the state of mind from being able to discuss and contemplate more important matters, such as philosophical subjects. In addition, the Greeks realized that the ecosystem played a chief role in the characteristics of the final wine. Consequently, they were the first to create wine laws and appellations of origin, with anyone violating them receiving a severe penalty.

Wine in Ancient Rome

After the Greeks, the Romans took over wine production in 1000 BC and made significant contributions to winemaking. They began classifying most grape varieties and invented the wooden wine barrel, even though the French were the ones to perfect oak aging. On top of this, the Romans were the first that used glass wine bottles. By far, the oldest wine bottle dates back to 325 AD. At that time, corking had been invented. However, they preferred to use a floating olive oil layer on their wine to protect it instead of corking the wine bottle.

After Carthage fell to the Romans in 146 BC, Cato wrote the first book on winemaking called De Agi Cultura. In the same way as the Greeks, the Romans enjoyed drinking wine at symposiums where philosophical debates took place. In this way, wine became a product associated with sophistication.

Winemaking in the Middle Ages

In the Middle Ages, Benedictine monks spread wine knowledge to Western Europe since wine is an essential part of the Holy Communion. However, the wine distributed by the Catholic Church was watered down. The Church did not approve of drunkenness. Therefore, even though wine consumption spread, it needed the French aristocracy’s intervention to become the drink we know today.

By 1725, Bordeaux had classified the best red wines it produced. That said, the official classification appeared in 1855, about a century later. It divided the wines into 5 ranks or crus. Following the French Revolution in 1789, the newly founded French Republic removed feudal privileges from the Catholic Clergy and French nobles, distributing them to peasants. That was vital for wine development since the prosperity of wine growers depended on the success of their vineyards.

American Innovation

After the European grape growers defeated the Phylloxera threat in the 19th Century, they began cultivating grapevines on American soil. That lasted until late in the Industrial Revolution, when the growth of the wine industry was territorial and technical. Since that point, European winemaking traditions were the norm.

In 1957, James D. Zellerbach, a diplomat, opened a winery in Sonoma County dedicated to his wife and modeled after the methods of Clos de Vougeot in Burgundy, France. By combining European tradition with American innovation, the Hanzell winery, as it was named, became the first to use stainless steel tanks for fermentation and to import oak barrels directly from France. At the same time, it had a laboratory on its premises for analysis and monitoring of the grape fermentation process, this provision is now a standard part of modern wineries.

Creation of Wine Bottle

As previously mentioned, the Romans invented glass wine bottles. However, it took thousands of years for a company to produce uniform bottles in size and shape. In 1821, that happened for the first time in the history of wine with a British business. However, up until 1860, selling bottled wine was illegal in England. So wine was sold by the measure, with customers bringing their own bottles, identified with a personal seal. Up until the 1970s, wine bottles varied in size from 650 to 850 milliliters. Eventually, they developed to the world-standard volume of 750 milliliters (26.7 oz.) per wine bottle.

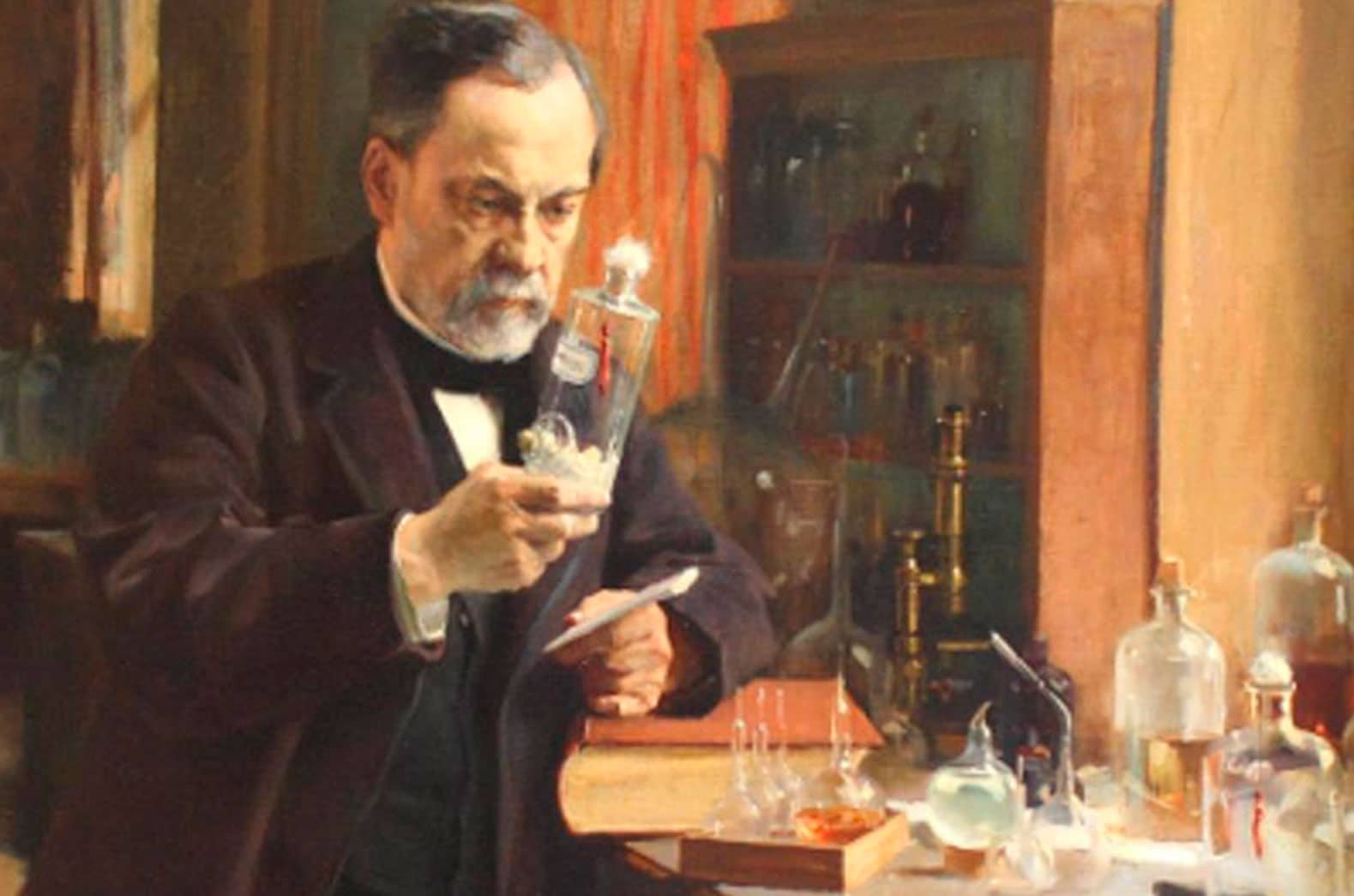

The Role of Louis Pasteur

Before modern winemaking, wine producers crushed the grapes with their feet before letting them soak in containers. The transfer of microorganisms from the feet of winemakers to the crushed fruits was believed to cause fermentation. But, it was not until the invention of the microscope in the 17th Century, that this hypothesis could be proved. The optical lens enabled the visualization of single-celled microorganisms for the first time in wine (and human) history.

The famous French microbiologist, Louis Pasteur, in 1857, after many experiments, showed that fermentation is caused by some fungi known as yeasts. A year earlier, in 1856, an accident took place at a sugar beetroot distillery that led to a pivotal discovery in wine, cheese, and yogurt production. Pasteur was assigned to investigate the issue and found that the spoiled beetroot mixture contained lactic acid instead of alcohol, which caused a sour taste. The beetroot mixture carried objects that were even smaller than yeasts. These were lactic acid bacteria responsible for causing malolactic fermentation (MLF) in wine. This incident helped us understand how fungi and bacteria perform during fermentation. Consequently, Pasteur proved living organisms are responsible for fermentation and that fermentation is a chemical and bacteria-related process.

Furthermore, Pasteur was the first to distinguish yeast types (saccharomyces apiculatus and saccharomyces elipsoideus). He even discovered that some yeasts convert sugar to alcohol, and others do not. In addition, the ingenious French microbiologist found that some yeasts stop functioning at 6% of alcohol, and some continue up to 17%. As such, he observed that high temperature kills off yeast, which is crucial in winemaking.

Pasteur’s discovery made it possible to sterilize the must, meaning killing off the wild strains by heating it to just below the boiling point and vaccinating the pasteurized juice with strain. However, modern winemakers do not pasteurize wine (only dairy products, such as cheese, milk, and yogurt). Instead, they add an amount of sulfur dioxide to prevent yeast from activating.

Few Words About the Yeasts

Yeasts need to reproduce, just like all living beings. In fact, in the first stage of fermentation (2 to 4 days), the yeast produces much more yeast. In other words, it reproduces. That is aerobic (contact with the oxygen in the air) fermentation. The anaerobic (without air) fermentation follows shortly after and produces most alcohol (ethanol). Under the best conditions, fermentation lasts about 2-3 weeks. Sometimes, though, fermentation can last for months.

How to End Fermentation?

Fermentation continues until the wine is completely dry without residual sugar or it can be stopped earlier to make sweet wines. The sweetness in the final wine ranges from off-dry to lusciously sweet. To end the fermentation, winemakers have to kill off or remove the yeast cells. They can do this with these methods:

- Adding alcohol to raise the level to 15% or more, as in Port or Sherry production.

- Adding more sulfur dioxide than usual or sorbic acid.

- Chilling the grape must.

- Filtering out the yeast cells with the use of a sterile filter.

- The point is that wines with residual yeast risk undergoing re-fermentation unless winemakers filter out that surplus.

White Wine From Black Grapes

For the most part, grapes have clear-colored juice, even if the skins are white (green) or back (purple-red). Now, pigmentation comes from the grape skins. Bear in mind that black grapes can produce white wines, too. By pressing the fruit and dividing (separating the clear juice from the pigmented skins before fermentation occurs) a white wine juice is given. In fact, using this technique, winemakers produce White Zinfandel and Blanc de Noirs (literally white from blacks). Consequently, the more contact between the grape juice and the skins, the more intense the extracted color from the skins would be.

What Is Alcoholic Fermentation?

Alcoholic fermentation is the conversation of sugar into alcohol and carbon dioxide through the action of yeast. The other by-products of this process are heat and flavor. Saccharomyces cerevisiae is the name of the yeast species responsible for fermentation. It is preferred to other yeasts due to its tolerance to high levels of alcohol and sulfur dioxide. Alcoholic fermentation does not start if the temperature is below 41°F (5°C) and should continue naturally until all the sugar has been consumed.

In addition, fermentation may stop before all the sugar is consumed. That happens if the yeast runs out of required nutrients or if the temperature exceeds 95°F (35°C). When the sugar concentration in the juice is high, the combination of high sugar levels and alcohol can be enough to stop the yeast from functioning. In extreme situations, the sugar level is so high that the yeast may struggle to start fermentation in the first place.

What Is Malolactic Fermentation?

Malolactic fermentation, or MLF, takes place once alcoholic fermentation has finished. It is carried out by lactic acid bacteria, which convert the tart malic grape acid into lactic acids.

MLF softens acidity, creates buttery and brioche bread flavors, and produces carbon dioxide. It can be encouraged by raising the wine temperature and by avoiding adding sulfites after the fermentation. It can also be avoided via storage at cool temperatures or filtering out the lactic acid bacteria.

How to Produce White Wine?

In general, white winemaking is less involved compared to red winemaking. The basic steps are grape picking, sorting, destemming, crushing, skin contact, pressing, clarifying, alcoholic fermentation, racking off gross lees, packaging, and selling. Depending on the winemaker’s desire, white wine may also undergo malolactic fermentation, blending, maturation, clarification, and stabilization.

Throughout white winemaking, many crucial decisions need to be made about skin contact, juice clarity, fermentation temperature and vessel, and maturation choices.

Skin Contact

In most cases, the juice spends little time with the grape skins to reduce oxidation risk. After harvest, the grapes are picked and crushed to release the free-run juice. This juice is separated, and the rest of the grape must go to the pressing machine. Some winemakers choose a different approach and load the press with whole bunches of uncrushed grapes to limit skin contact. That is a gentle process, reducing the risk of oxidation, and leads to a wine with pronounced freshness and varietal character.

Grape Juice Clarity

The freshly pressed grape juice contains compounds from the grape skins and the pulp. If the juice ferments in this state, unpleasant aromas form and the fermentation can stop prematurely. Consequently, the juice has to be clarified before fermentation begins. That is done using the same techniques used to clean wine before bottling, such as fining, filtration, settling, and centrifugation.

Some winemakers choose to keep a small amount of the grape fragments in the juice. It is believed that they make the wine less susceptible to oxidation and add complexity and a richer texture. However, if the intended wine is meant to show pure varietal character, this technique is avoided.

Fermentation Temperature and Vessel

The optimum temperature for white wine fermenting is between 12-22°C (54-72°C). Fermenting at too low a temperature results in the creation of pear aromas and might fail to capture varietal character. Fermentation at higher temperatures encourages complex, non-fruit aromas to develop.

Temperature controlling machines are used to prevent temperatures from running too high. Yet, this is only possible in stainless steel fermenting vessels. If fermenting in barrels, controlling the temperature is challenging. That said, the small size of the barrels and the fact that they are stored in cool cellars means that they tend to dissipate heat efficiently. In every case, fermentation in barrels runs at the higher end of the temperature range.

Maturation Options

After fermentation, white wine may mature in oak or be stored in inert tanks with or without oak chips or staves, which add a charred wood sensation to the final wine. On top of this, winemakers may prefer to use fine lees to add texture and flavor to their wine. And they may also choose to allow or prevent malolactic fermentation.

Blending

Blending helps winemakers to improve wine consistency and enhance wine balance. In general, white wines are based on pure primary fruit flavors, so blending has the role of ensuring consistency rather than enhancing complexity. The reverse, however, is true for non-aromatic varieties, such as Chardonnay, where the winemaker uses amounts of lees contact, MLF, and oak influence on different portions of the wine. These portions are then blended together to achieve a complex style.

Clarification and Stabilization

Nearly every white wine undergoes some form of fining and filtration to improve clarity and stability. The pale color of most white wines compared to red ones make sediment readily apparent. Further, whites containing some residual sugars are at risk from microbiological infection. In such cases, the winemaker uses sterile filters to remove bacteria or yeast that might be present.

How to Produce Red Wine?

Red winemaking is way more involved than white winemaking because the grapes must be fermented on their skins to extract color and tannins. That is achieved by including the skins in the fermentation vessel. However, this process leads to two consequences: Firstly, more options must be considered before, during, and after fermentation than in white winemaking. Secondly, pressing happens post fermentation.

And when making red wine, malolactic fermentation (MLF) is a standard practice rather than choice, as in white winemaking.

Crushed Fruit Fermentation

The majority of grapes used in red winemaking are destemmed and crushed. For that to happen, some other techniques are applied:

Pre-fermentation Extraction

After the fruit has been crushed, winemakers prefer to let the grapes macerate at low temperatures before allowing the fermentation to start. This is referred to as cold maceration or cold soaking. The aim of this maceration is to extract color and flavor compounds.

Temperature Control During Fermentation

Red wine fermentation temperatures range between 20-32°C (68-90°F), depending on the wine style. These high temperatures are essential to aid the extraction of flavor, tannin, and color. That said, winemakers must be extra careful to ensure that the temperature does not go over 35°C (95°F) as it might kill the yeast. So, precise temperature control during fermentation enables the winemaker to influence the extracted amounts of tannin, color, and flavor.

Cap Management Techniques

During fermentation, a fermenting red wine has a thick mass of pulp and skins on its surface. This mass is called a cap. If the cap is left to float, color, tannin, and flavor will be extracted from it, and the final wine will be uninviting. For this reason, there are many different cap management techniques a winemaker uses to overcome this end result. These methods might be combined or used separately at various stages of the fermentation.

Punching down: Traditionally, the cap was punched down by hand with wooden paddles. Today, however, the same effect is achieved with mechanical addles. This technique is very effective at extracting color and tannin. But winemakers need to take extra care not to overwork the cap by punching down too vigorously.

Pumping over: Involves drawing off fermenting juice from the bottom of the vat and pumping it up on the top, wetting the cap. This is a good way of dissipating heat and oxygenating the juice.

Rack and return: The fermenting red wine is drained from the fermentation vat into another vessel, leaving the cap behind. Then the grape juice is pumped back on top of the cap. This is a very extractive technique, so it is issued only once or twice during fermentation.

Rotary fermenters: Sometimes, fermentation takes place in horizontal tanks that rotate, which ensures that the juice always remains in contact with the skins.

Fermentation Vessels

Red wine fermentation can take place in oak, concrete, or stainless steel vessels. That being said, fermentation in oak barrels is impractical for red wines, as it would be almost impossible to make efficient contact between the skins and the juice.

Post Fermentation Extraction

Maceration after fermentation encourages better extraction of tannin, which, however, may not be desirable. The length of time that the wine stays on its skins once the fermentation is complete depends on the wine style.

Press Wine

After maceration, the free-run wine is extracted from the skins, and the remaining mass is pressed to create press wine. At the start of pressing, this pressed wine may be similar in composition to the free-run wine, but as pressing continues, the wine becomes deeper in color and higher in tannin levels. Some winemakers may separate the wine at different stages in the pressing to adjust color and tannin in the final wine.

Whole Bunch Fermentation

Some red wines are made only with crushed fruit. However, others are made with whole bunches of uncrushed grapes. In some cases, the uncrushed grapes may make up the entire vessel, while in others, only a small percentage may be used to make a more subtle contribution to the wine flavor. If whole bunches are used, the winemaker must ensure that the grape stems are ripe, as if not, the tannins in the stems will bestow an undesirable astringent taste.

The point of this technique is to create an oxygen-free environment for the uncrushed fruit. The lack of oxygen enables the berries to create alcohol in their cells without the involvement of yeast. This is known as intracellular fermentation. Secondly, distinct fruity aromas are created inside the berry, giving unique qualities to the resulting wines. The two main forms of whole bunch fermentation are: carbonic maceration and semi-carbonic maceration.

Maturation options

The option of whether or not to use oak is the most important decision when it comes to pre-bottling maturation in red wine production.

Generally speaking, oak is widely used in red winemaking. Winemakers may use oak barrels to mature their wines. Additionally, they might use oak staves or wood chips. Before some decades, premium red wines used to age in small new oak barrels. However, this is not the case anymore in most wine regions.

Blending

The blending of two or more grape varieties is common in red wine production and is often used to enhance or balance out aspects of the wine, such as acidity, flavor, or tannin. In addition, the wine’s complexity is enhanced by blending wine matured in oak vessels of different ages and tasting levels. And by combining oak-aged wines with wines matured in concrete or stainless-steel vessels, winemakers achieve a more subtle oak influence.

Clarification and Stabilization

The majority of red wines will undergo some form of fining and filtration to improve the clarity and stability of the wine. However, some winemakers avoid these processes believing they harm the wines’ structure.

Bottling Equipment

Bottling equipment varies from siphon hoses, hard corking, labeling machines, and funnels to modern, sanitized, and sterile automated bottling machinery. The bottling process includes methods of bottle sterilizing, installing the corks, standardizing the wine fill level, covering the bottles with capsules, attaching the paper labels, and storing the bottles in boxes for shipment or storage.

Additionally, before bottling, some winemakers carry out blending trials. They combine samples of cuvées from different grape varieties, vineyards, or vintages to discover how wine tastes best. When the blend taste matches the expectations, it is applied to the rest of the produced wine and bottled.

Early consuming wines are kept for long periods in refrigerated tanks to preserve freshness and floral characteristics. On top of that, bear in mind that wine is bottled at several points within a year to replenish depleted store shelves.

How to Make Wine at Home?

Making wine at home might seem complicated, but rest assured that it is as challenging as making sourdough bread. That said, producing wine at home requires time and several specialized tools.

The following instructions will make about 5 gallons of wine, which is fine for those exploring home wine production. The grapes can be sourced from grape growers or wineries, while the specialized equipment is available at many websites and wine-making stores.

Step 1: Purchase the Grapes

For starters, buy the best quality grapes you can afford since they are the primary ingredient. In total, you will need about 70 pounds of grapes. For the best possible price and quality, choose to buy your grape variety from a local vineyard instead of a designated wine merchant.

Using grape concentrate will not cut it, as the final wine will end up tasting sweeter and less complex than desired. That said, frozen wine grape juice or grape must, which is juice with grape skins together, is as good as fresh grapes.

Step 2: Crushing and Stomping Time

If you bought pre-crushed grape must or juice, then you can start fermenting the grapes. If not, you have to crush and press them to get the juice out of them.

Begin by placing the grapes in a large and clean container. Wash your feet with soap and rinse. Then, hop on the grape bunches and stomp them by foot. The sensation might feel weird, but this is quite normal. Remember that you cannot hurt the grapes. Therefore, pressing down vigorously until the bunches are crushed, and the juice is released, is OK.

If you intend to produce red wine, removing some of the berries from the stems during crushing is good. That helps your final wine obtain the desired red color. Aim to ferment the juice, skins, and seeds together. You could try to remove more stems if you prefer, but if you choose not to, don’t worry. The worst that can happen is you produce a wine with a similar texture to a Beaujolais nouveau.

However, if you seek to produce white wines, you only need to ferment the released grape juice. So, pour said juice through a funnel into a carboy, then gently press the leftover skins and stems through a colander into a bucket to collect any remaining juice. Additionally, you can put the skins and seeds into a cloth bag and get the last bits of extra juice.

Step 3A: White Wine Fermentation

To produce five gallons of palatable wine, start with 5.25 gallons of white grape must. Pour said juice into a carboy larger than the volume you are going to ferment. As the wine ferments, it foams and expands and might ooze out the top.

At first, the white grape juice will have a green hue with golden reflections, such as a Sauvignon Blanc, but eventually, it will turn brown after it is pressed and starts to ferment. As time goes by, though, it will become golden again. On top of this, use an airlock to keep oxygen out and enable the carbon dioxide produced during fermentation to escape.

At this point, add the wine yeast, always according to the instructions found on the packet. Next, strive to keep the juice at room temperature. Within a day or two, it will start emitting carbon dioxide, signaling the start of the fermentation.

Take extra care to remove the stopper once a day to stir the fermenting wine, as the lees will begin settling to the bottom of the container. If the fermentation process of wine speeds up and the liquid foams out of the container, aim to cool the vessel by placing it in the fridge for a few hours.

Step 3B: Red Wine Fermentation

Producing red wine does not require an airlock during fermentation. Contrary to white wine production, red wines can ferment in an open container with just a cloth towel on top to keep away dust and fruit flies.

Add wine yeast, and stir well. The mixture will begin to ferment within 12 hours. In addition, keep in mind, you have to punch red wines down twice per day during fermentation. While doing this, you will see a cap of grape skins floated to the top. Once you notice it, you have to regularly submerge the skins into the wine to keep them wet. That helps in the extraction of color, flavor compounds, and tannins. So, keep pushing the skins down with a paddle or a wooden stick.

Red wines warm up to 80°F (27°C) when fermentation is going strong to complete this extraction. To make sure the temperature is correct, double-check it with a weather thermometer if you have one handy.

Step 4: Evaluating Sugar Levels

For this step, you need to test the sugar levels of the grape juice periodically. A hydrometer in a graduated cylinder is required. The measurement is degrees Brix, which shows sugar percentage. The grape juice will begin somewhere between 20-26 degrees Brix and be reduced to minus-2 Brix when the fermentation is complete.

White wine fermentation can last from days to weeks. However, the approximate time it takes for the wine to ferment depends on the temperature. If the room where the fermentation takes place is cool, then it will take longer. As to red wines, they reach warm temperatures in about 2 weeks of fermentation, like when produced in a professional winery.

Once this process is over, separate the fermented wine from the gross lees by pouring the wine into a 5-gallon carboy for maturation.

For white wines, siphon off the juice to leave behind most of the lees and throw them away. For reds, transfer the grape juice to the carboy and press the skins to squeeze any extra fluid. Add this juice to the carboy and close it with an airlock to protect the wine from oxidation.

Step 5: Protection Against Premature Oxidation

The most significant step after fermentation is to protect your wine from premature oxidation. Therefore, after fermentation, do not allow more carbon dioxide to escape. Instead, keep the carboy topped up and avoid opening it. If needed, do not be shy, and top up with some quality commercial wine.

Now, it is time to add sulfites. You need to raise the wine’s sulfur dioxide content to a moderate level of about 60 per million (ppm). This sulfur dioxide protects the wine from oxidation by keeping it fresh, removing harmful microorganisms, and vinegar bacteria. Consequently, with sulfites, you ensure you will not end up with balsamic vinegar.

Tip: Sulfites, while helping keep the wine clean, are not a substitute for meticulously clean funnels, containers, and other wine equipment. It is unnecessary to sterilize everything, even though it would help. That said, your equipment must be sanitary.

Step 6: Long-term Storage

Store the carboy in a cool place away from direct light while checking at regular intervals for a dry airlock or loose stopper. Every week or two, stir the lees to improve the texture. While doing this, sip a bit of your wine, and if it is something you find enjoyable, go ahead and bottle the wine. For the most part, white wines need 5 to 10 months to mature in a carboy. Reds might take 6 months to 1 year or more, depending on the grape variety.

Before bottling, aim to rack red wines once or twice. That is unless you are producing a Port. Use a siphon and pour the clear wine into another container to keep the lees out. Then, return the wine to the carboy. Unlike reds, white wines may remain on their lees continuously until bottling.

Step 7: Bottling

For this step, you take the wine out of the carboy and pour it into the bottles. While doing so, avoid disturbing the lees and exposing the wine to air. So, siphon the wine into the bottles. Try to fill each bottle to the top while allowing half an inch of space for the cork to rest.

To cork the bottles, you must use a manual corker. This tool can be bought from a wine store or even rented. Furthermore, you may take your bottles to a winery, and they will cork them for you at a price.

Finally, the metallic capsules on commercial wines are tough to apply to home wines without expensive equipment, namely a spinner. Brew shops, though, offer plastic versions that cover the bottle tops and still manage to look nice. These plastic capsules will shrink to fit when held over a fire or a stove burner. But be careful when doing this to avoid getting burned.

Give your wine a few weeks to age in the bottle to reach its true potential. After, uncork it and enjoy the fruit of your labor!

To conclude, follow these wine making tips to produce the most delightful and palatable homemade wine!

What Are the Six Steps in Wine Production?

As mentioned before, there are six steps when producing wine:

Harvest: The grapes are picked from the vines when they have the desired concentration of acidity, flavor, and sweetness.

Destemming: Harvesting is done by hand or mechanically. Once the grapes are picked, they are sorted at the winery. Then, they are destemmed and crushed to release their juice.

Alcoholic fermentation: The grape juice or must is moved into stainless steel tanks or oak barrels to ferment for about 2 weeks. Without oxygen, yeasts convert the sugars of the wine juice into alcohol and carbon dioxide. After yeasts die, they form sediment in the bottom of the tank and remain there with the seeds and pulp fragments of the grapes, forming the lees. Letting the wine rest with the lees or stirring less during fermentation increases the stability and structure of the final wine.

Pressing: Pressing is the method of extracting the grape juice. White wines are pressed before the first fermentation, while reds when the fermentation is over.

Aging: Winemakers may choose to age their wines after fermentation in oak barrels to add flavors of toastiness, clove, cinnamon spice, smoke, and charred wood.

Bottling: When the final wine is considered stable, clear, and complete, bottling takes place. When bottled, sunlight and exposure to the air, which causes premature oxidation, are not a threat to the wine.

How Does Wine Ferment?

Alcoholic fermentation is the process that produces wine. It begins once the juice from crushed grapes or must go into stainless steel tanks. Then, the grape sugars turn into alcohol in a complete temperature and oxygen-controlled environment.

There is also the possibility of secondary fermentation taking place. This second fermentation is more common when making red wine. It is known as malolactic fermentation (MLF). During MLF, the strong-tasting acid (malic acid) converts into a softer one (lactic acid) and increases the complexity, flavors, and aromas of fermenting wine.

What Is Winemaking Called?

The wine making process is also called vinification. It refers to the production of wine, starting with the selection of the grape berries, their conversion into alcohol through alcoholic fermentation, and the bottling of the produced liquid.

Furthermore, a winemaker is also known as a vintner, while the growing of grapes is viticulture. Vitiscience is the scientific research of wine grapes and grapevines.

How Do You Make Homemade Wine Stronger?

Many producers of homemade wine argue that adding extra yeast and sugar to a fermenting wine makes it stronger. And that is true to some extent. As such, higher levels of sugar added to a fermenting wine result in higher alcohol percentages. But, keep in mind that while adding sugar does increase the overall alcohol percentage, it also enhances other aspects of the alcohol.

If you opt to add sugar to your homemade wine, take extra care to choose the relevant yeast. The reason for this is that most yeasts used for making wine die once alcohol reaches 20%. So, note that down when producing homemade wine.

What is more, there is another way to make your wine stronger. And that is through fortification. Add distilled spirits, such as vodka, rum, or brandy to raise the alcohol percentage. However, do not overdo it.

What Name is Given to Liquid Right Before It Turns to Wine?

The juice or grape liquid right before it becomes wine is called must, and it is the crushed grape juice. Also, it contains grape seeds, skins, and stems. The name derives from the Latin vinum mustum, meaning young (unfermented) wine.

What Is a Master Winemaker Called?

As previously mentioned, a winemaker or vintner is someone engaging in wine production and winemaking. Likewise, a master of wine is known as a vintner, oenologist, or sommelier. That said, a sommelier is typically someone with deep knowledge of wine service, while a master of wine works exclusively in the making, production, and distribution of wine. So, be sure to know the difference between a sommelier and a master winemaker.

Moreover, in the United States, master winemakers are the heads of winemaking at domestic wineries.

How Long Before You Can Drink Homemade Wine?

You have to wait 2 months before drinking your homemade wine. However, for the most part, winemakers advise against drinking home-produced wine after just 2 months. The more you allow the wine to age, the tastier it will be.

Is it OK to Drink Wine that Is Still Fermenting?

The answer is positive since it is completely safe to drink wine that is still fermenting. In fact, as the wine ferments, you have to sip it occasionally to see how the flavors develop. On that note, in Vienna, the capital of Austria, it is common to drink fermenting wine during the harvesting season at wine bars. In this way, patrons have the chance to observe distinctive flavors and aromas that are rarely present in bottled wines, such as banana and kiwi notes.

How Much Alcohol is in Homemade Wine?

Generally speaking, wine, including homemade wine, has a standard alcoholic content. That said, the actual alcoholic concentration depends on the grape variety and wine style. For example, a complicated Cabernet Sauvignon will have different alcohol content than a sparkling Prosecco. In every case, the alcohol level in wine ranges from 8 to 15% ABV.

Conclusion

We hope this guide is indeed a complete introduction to enology and solves every question posed by wine enthusiasts.

Wine is an intricate and complex matter. So, even though we tried to cover everything, at least on a basic level, related to wine, there is still tons to learn. As such, do not take this guide as a finite wine handbook but as a great starting point to explore the fascinating world of wine. Besides, how wine is made and how to make wine at home are complicated subjects.

The bottom line is this enology guide serves as winemaking for dummies material and should be treated as such!